TECHNOLOGY

Here’s how it works

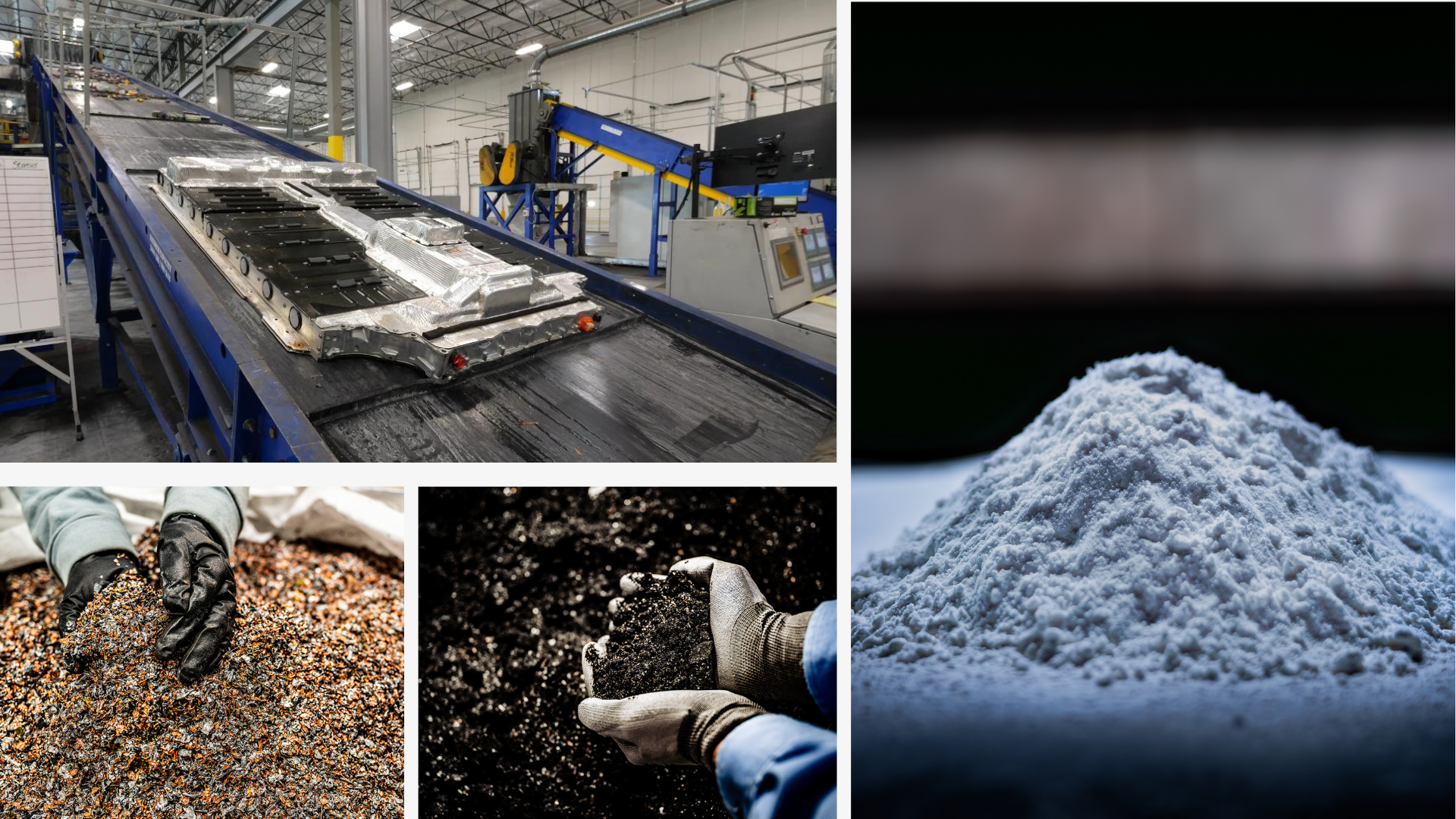

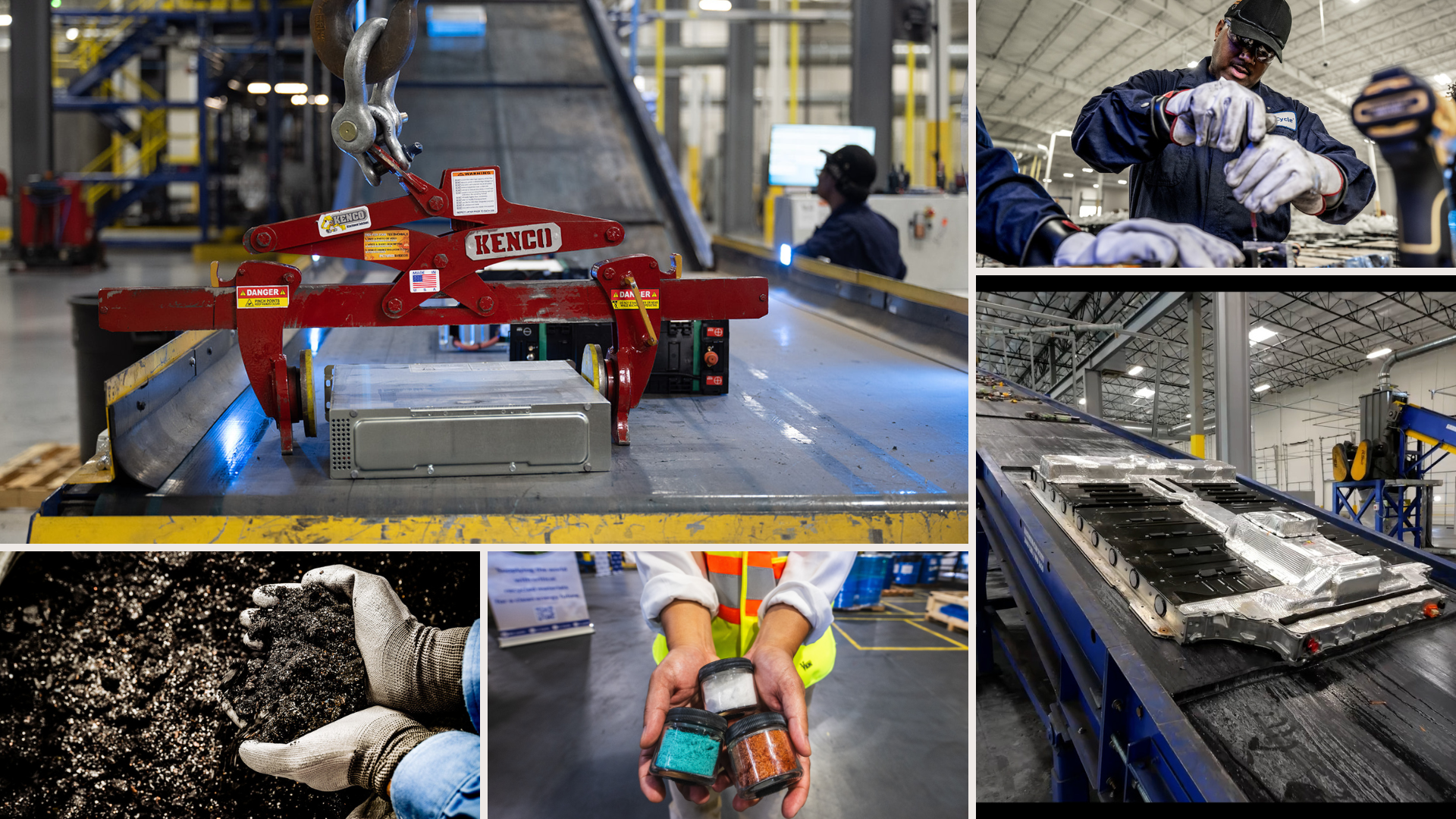

SAFE, SUBMERGED SHREDDING OF BATTERIES AND MANUFACTURING SCRAP

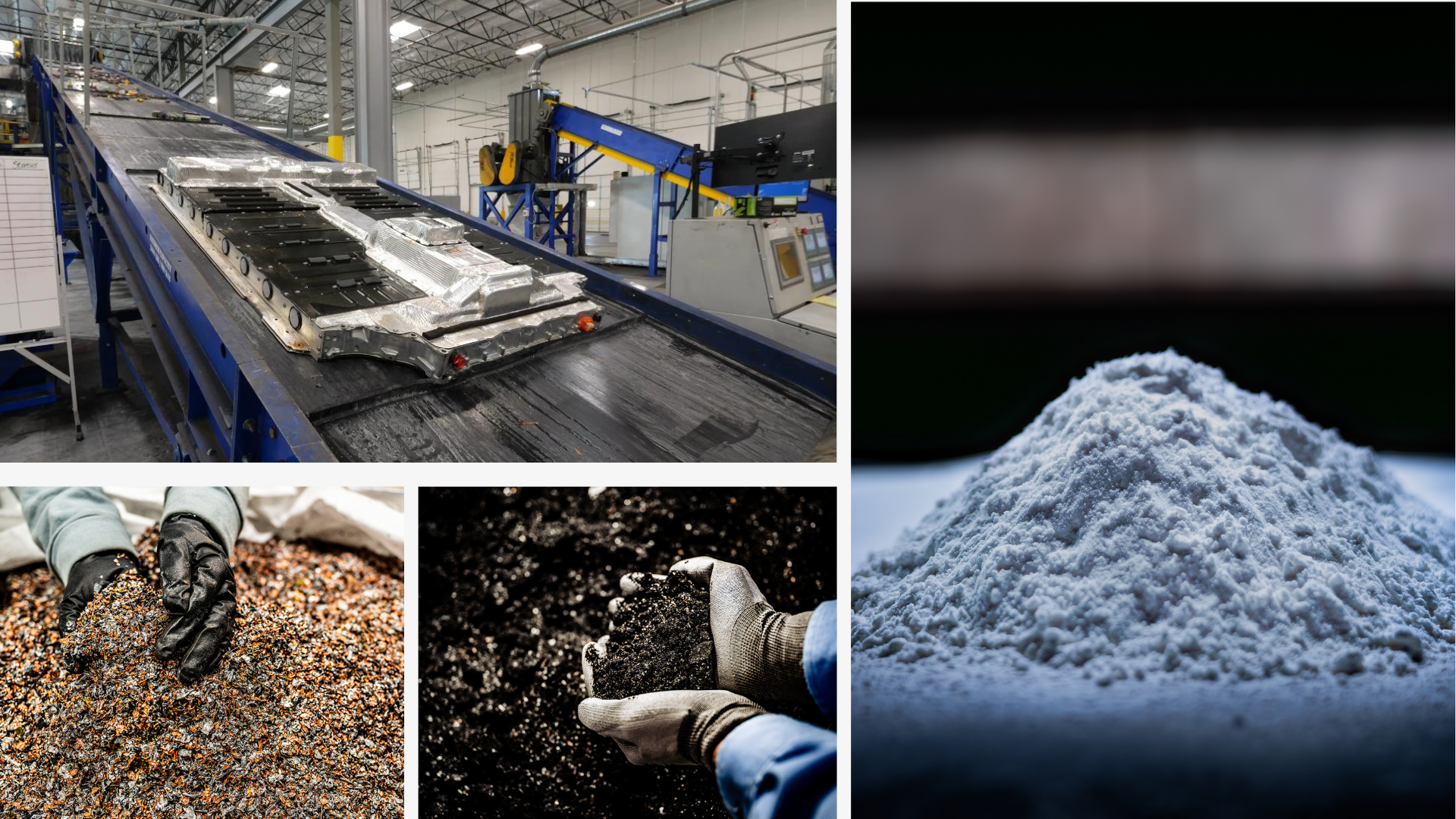

HYDROMETALLURGICAL PROCESSING TO PRODUCE CRITICAL BATTERY MATERIALS

WHY IT’S IMPORTANT

Generation 3 Spokes can process full pack EV batteries without the need to dismantle or discharge.

Our technology enables up to a 95% recovery rate to return critical materials back to the supply chain.

We are able to safely receive and recycle all types of lithium-ion batteries regardless of form factor and state of charge, as well as all types of battery manufacturing scrap. We can also process damaged, defective or recalled batteries.

Li-Cycle’s Hubs are expected to produce high-quality, critical battery materials, including battery-grade lithium carbonate.