May 24, 2021

This thought leadership article was contributed by Kunal Phalpher, Li-Cycle

May 22, 2021

Given ongoing, pressing concerns surrounding climate change, renewable energy has become a topic that is more widespread than ever before. Statistics and figures recently released by NASA reveal the global average surface temperature was just shy of one degree Celsius warmer than the 20th century global average. It is clear that progressive strides towards a greener future are vital.

With fossil fuels being a major contributor to the greenhouse gas emissions driving climate change, the obvious solution lies in renewable energy production and storage. While this seems like an easy solution in the abstract, it is critical that we tamp the idealistic nature of this idea with realism, lest we trade one harmful source of energy for another in our rush to find alternate energy sources.

While this may sound extreme, it is not. The positive impacts of renewable, non-harmful energy sources are well understood. The issue here, however, lies in energy storage, with lithium-ion (Li-ion) batteries being considered the new gold standard. Widely used in smartphones, tablets, laptops, electric vehicles and other devices, these powerful batteries are perfect for efficient energy storage — something that can be attributed to their high energy density and longer lifespan than other available battery options. The problem is that one of the main battery components — lithium — still relies mostly on an energy-intensive mining production process.

What exactly is lithium? In its elemental form, lithium is a soft, silvery-white alkali metal that is both highly reactive and flammable. It is an essential part of Li-ion batteries due to its low electrode potential and low atomic mass, which gives it a high charge and power-to-weight ratio. This enables the finished batteries to be more compact and powerful than other rechargeable batteries. Like other naturally occurring minerals, lithium is, unfortunately, a finite resource that comes with an energy-intensive mining process. The traditional extraction process itself may reduce the potential climate benefits when it comes to its role in minimizing harmful emissions.

The ‘why’ in this instance is clear: The extraction of any raw material is costly, energy intensive, and ultimately harmful to the environment. Common mining practices may result in the loss of biodiversity, as well as erosion, sinkholes, and both ground and surface water contamination. In addition to these harmful aspects, the majority of the world’s lithium mines are situated at a considerable distance from battery manufacturing plants. According to the US Geological Survey, the world’s most lithium-rich countries are Chile, Argentina, Bolivia, Australia and China. The energy required to transport the material internationally results in the generation of a considerable amount of carbon dioxide throughout the entire process.

Moreover, it takes around 500,000 gallons of water to extract one metric ton of lithium using traditional methods. The water is used to create a mineral-rich mixture or brine required to obtain lithium from salt flats. This mixture is then left to evaporate, and after sufficient filtration, lithium carbonate can be extracted. However, the process itself harms the soil — since toxic chemicals can leak from the evaporation pools — and it causes air contamination.

It’s essential that we work towards minimizing this method of gathering lithium and we must identify new methods without drawbacks. Luckily, we don’t have to look far, as the most viable solution is a staple of sustainability: recycling. Although the first step is to extract lithium from primary sources, recycling existing lithium will reduce our dependence on primary sources and it will help extend the lifecycle of the lithium that is currently being used on the market, or has already been spent. Recovering used lithium can also help create a domestic supply of the resource, thereby reducing the environmental and economic transportation costs.

A report from C&EN found that at the end of 2020, China alone had generated approximately half a million metric tons of spent Li-ion batteries. The same report projects that this figure will reach 2 million metric tons per year by 2030. Landfilling these resources is an economic and environmental burden, while recycling — also known as “urban mining” — is the key to solving this problem.

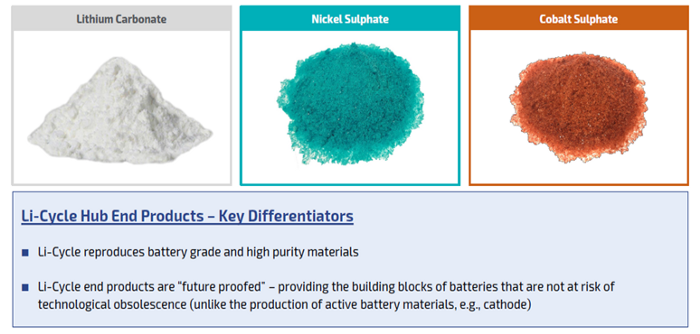

Having established this, it’s important to note that traditional Li-ion battery recycling methods involving thermal or extreme-heat also come with a downside. These methods only recover around 40 to 50 percent of the valuable resources (like cobalt, nickel, and copper) found within Li-ion batteries. Additionally, the lithium is not economically recoverable to a high grade suitable for use in battery production. These thermal methods are also energy intensive, produce a large amount of solid and gas waste, and do not recycle nearly enough of the components to make them the viable long-term solution for battery recycling.

Thankfully, new methods of recycling have emerged in recent years with the potential to reclaim and recycle up to 95 percent of resources. Instead of thermal processing, the spent batteries undergo a two-stage process of mechanical shredding and wet-chemistry refinement. This method allows the lithium that was previously lost, to be reclaimed. The process is an all-around more attractive option, as it not only negates the pollution output and energy required for thermal processing, but it also removes the need for extensive mining, refinement, and the transportation of virgin lithium.

The way in which we power our world is changing. For now, lithium is one of the key players in our transition away from fossil fuels and towards a cleaner, greener future. Through urban mining and new, innovative recycling processes, we are now better able to obtain lithium in a more sustainable way. Select companies are already ushering in these processes, helping the world to realize a cleaner future today.